Introduction

In at the present time’s rapid-paced commercial international, downtime might be a organisation's worst enemy. It now not in basic terms leads to monetary losses however also affects productivity and employee morale. What if you might take proactive measures to prevent your units jogging easily? By imposing powerful maintenance and calibration innovations, enterprises can dodge unexpected shutdowns and protect operational effectivity. This article will delve into the intricacies of averting downtime with proactive software upkeep and calibration, exploring most effective practices, methodologies, and true-world applications.

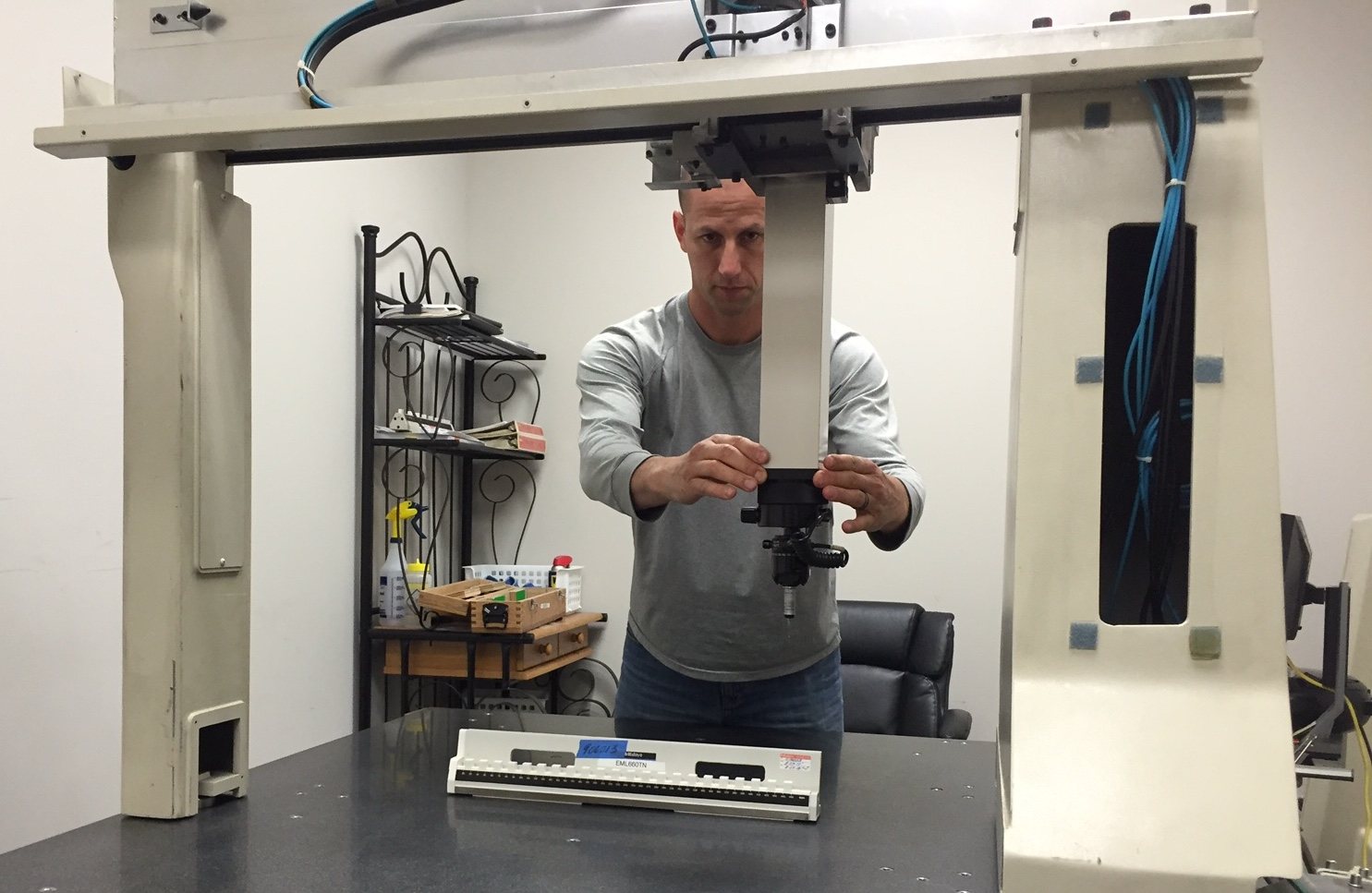

Avoiding Downtime with Proactive Instrument Maintenance and Calibration

Proactive software protection and calibration are considered necessary aspects of an productive operational procedure. But why is it so crucial? Simply positioned, those practices assistance guarantee that units operate wisely and reliably, preventing steeply-priced failures that may cause significant downtime.

Understanding Instrumentation in Industry

What Are Industrial Instruments?

Industrial devices are specialized instruments used for measuring, controlling, and tracking a number of bodily parameters akin to temperature, tension, float, and stage. These instruments play a vital function in ensuring strategies https://freebestads.com/492/posts/3/25/2079286.html run smoothly.

The Importance of Accurate Measurements

Accurate measurements are considered necessary for %%!%%53103524-third-45ec-9be9-82f57821803c%%!%% product good quality and compliance with regulatory criteria. Any waft in dimension can cause defects or damaging circumstances.

The Cost of Downtime in Industry

Financial Implications

- Lost Revenue: Every minute of downtime translates into misplaced gross sales. Operational Costs: Costs incurred from repairs or beyond regular time exertions. Reputation Damage: Prolonged downtimes can harm a organization's acceptance between prospects.

Impact on Productivity

Downtime disrupts workflows premiere to lowered productiveness. Employees can also face delays in their duties due to the machinery disasters.

What Is Proactive Maintenance?

Proactive protection comprises awaiting energy worries beforehand they ensue as opposed to awaiting them to appear. Here's how it differs from reactive repairs:

- Reactive Maintenance: Fixing gear after it fails. Proactive Maintenance: Regular assessments and servicing centered on utilization styles.

Benefits of Proactive Instrument Maintenance

Increased Reliability Reduced Unscheduled Downtime Extended Equipment Lifespan Enhanced Safety Standards Improved Compliance with RegulationsKey Strategies for Implementing Proactive Maintenance

1. Establish a Routine Maintenance Schedule

Creating a agenda supports be sure that each one units take delivery of universal recognition elegant on organization thoughts.

2. Utilize Predictive Analytics

Predictive analytics can forecast achievable disasters primarily based on historical tips gathered from machinery use.

3. Train Your Staff

Investing in exercise people guarantees they keep in mind the value of renovation tactics and find out how to carry out them effectively.

Calibration: A Critical Component of Maintenance

Calibration is the technique of adjusting an tool's output or indication to healthy a general regular within special limits.

Why is Calibration Necessary?

Ensures accuracy. Maintains compliance with regulatory requisites. Prevents high-priced errors in creation methods.Best Practices for Calibration Procedures

- Develop same old running processes (SOPs) for calibration. Use certified reference ingredients. Maintain targeted documents of calibration occasions.

The Role of Technology in Proactive Maintenance

Advancements in technology have changed the way organisations mindset maintenance:

1. IoT Integration

Internet of Things (IoT) instruments let genuine-time monitoring of device functionality, sending alerts whilst concerns stand up.

2. Automated Reporting Systems

Automated systems assist tune preservation schedules and document completed paintings seamlessly.

Creating a Culture of Care Towards Instruments

Encouraging a culture that prioritizes maintenance ends in long-time period benefits:

- Promote accountability between workforce relating to software care. Recognize staff who adhere to ideally suited practices constantly.

FAQs About Avoiding Downtime with Proactive Instrument Maintenance and Calibration

1. What is the standard intention of proactive device maintenance?

The everyday function is to keep unexpected breakdowns by means of appearing ordinary checks and services and products on kit earlier than matters stand up.

2. How in general should always tools be calibrated?

Calibration frequency varies depending at the type of tool and its use; nonetheless it, it is basically beneficial as a minimum once a yr or in keeping with brand hints.

3. Can I perform renovation in-area?

Yes! With applicable guidance and supplies, many groups can control their own protection exercises with no trouble.

4. What are some symptoms that an software wishes calibration?

Signs might come with inconsistent readings, sudden variations in overall performance, or failing routine exams against requirements.

5. How does proactive preservation shop cash?

By cutting back downtime expenses linked to emergency maintenance and growing ordinary productiveness using legitimate operations.

6. Is there device possible for managing protection schedules?

Yes! There are varied Computerized Maintenance Management Systems (CMMS) to be had which will support cope with schedules comfortably when tracking compliance with rules.

Conclusion

In end, avoiding downtime by proactive tool preservation and calibration just mechanical calibration isn't simply most interesting follow; or not it's critical for %%!%%53103524-third-45ec-9be9-82f57821803c%%!%% operational performance in any industrial atmosphere. By making an investment time into growing tough routines that encompass both preventive measures and technological integration—corporations set themselves up for fulfillment even as minimizing hazards linked to poorly maintained methods or erroneous measurements.

Implementing those options provides peace of intellect realizing you've taken remarkable steps towards safeguarding your operations opposed to untimely interruptions attributable to unforeseen conditions—a win-win problem for all people concerned!